Line

& Boom Pumping

For the purposes of line pump pours, our company has in its fleet a Schwing truck mounted BPA 500 line pump.

Line pumping is a necessary component in the construction industry. Many projects only have the accessibility for a

line pump. Our company’s line pumping system consists of a steel pipe side up with minimal concrete hose at the end.

The steel allows the concrete to flow more freely than through a hose setup, and helps aid in preventing blockages, which

can occur more frequently in hose set ups. We also have the smallest concrete boom pump on the Western Slope with an

outrigger width of 12 feet, which makes it ideal for road work where only one lane will need to be closed, eliminating any

extra burden on the client. It has an unfolding height of 13 feet which makes it the best option for inside boom

pump applications, eliminating slick line and labor costs.

Shotcrete & Soil Retention

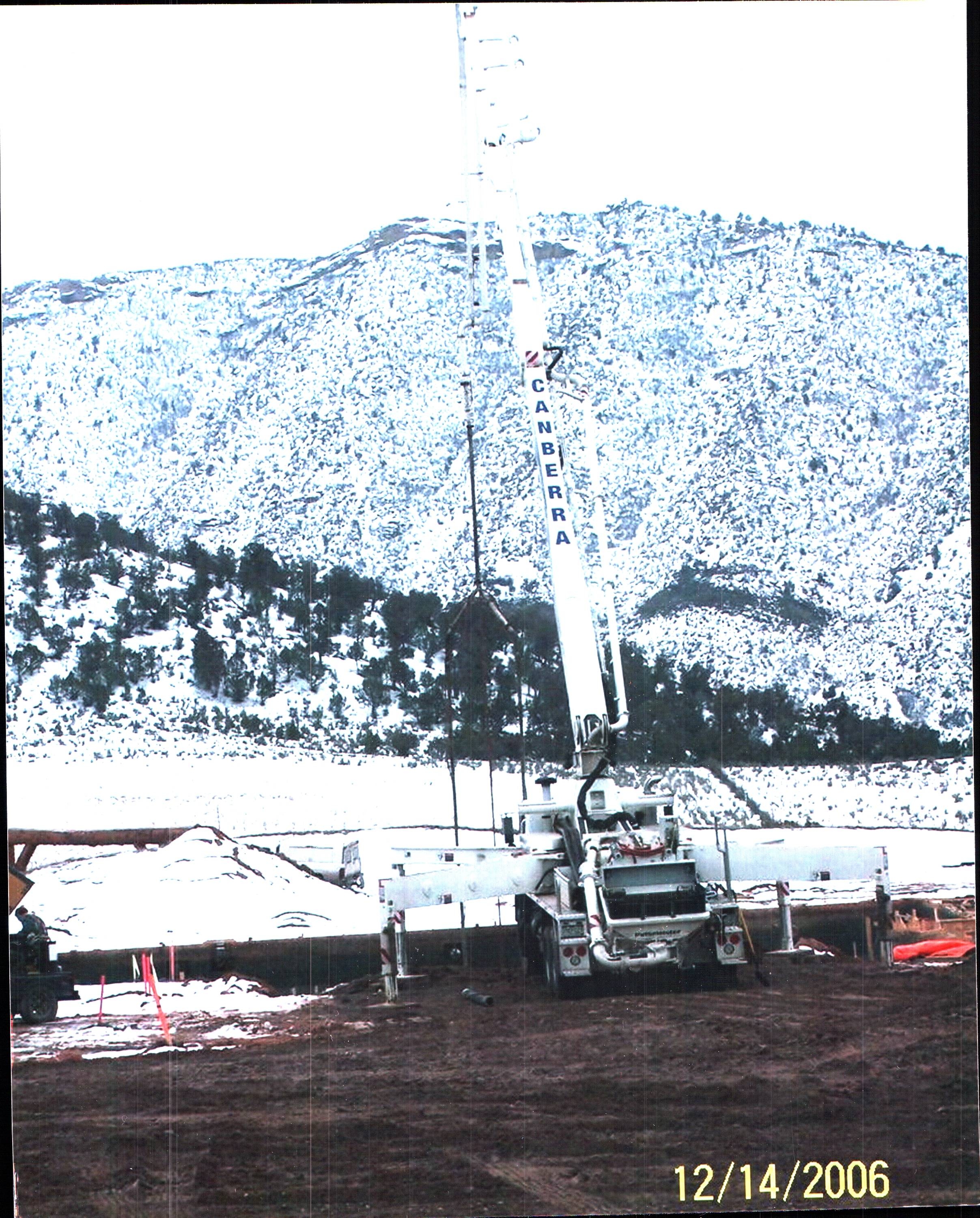

Canberra

Concrete Pumping designed a two hose shotcrete nozzle system for the ability to apply large areas of shotcrete at the same

time. This allows the project to move along considerably faster and resolve the problem of cold joints. We are specialists

in shotcrete and are certified by the ACI Shotcrete Association. Shotcrete applications include water features, pools

& spas.

Slabjacking

Slabjacking is a process that provides contractors

and homeowners the option to raise or void fill sunken slabs, in place of tearing out and replacing the concrete slab.

On many occasions it requires the process of core drilling into the slab to allow the placement of concrete directly into

the area of the void for the slab to raise or void effectively. In some cases, it may be necessary to drill more holes

during the slab jack process if the concrete is not flowing properly through the areas previously drilled. Once the

slab has been effectively raised or void filled, the cored pieces are inserted back into the holes to seal them. The

cored holes will be visible, looking like small circles. Slabjacking is very effective, but it is a process that requires

some guess work, being that it is impossible to see under the slabs. Any possible information a client can provide prior to

the procedure will be very helpful to both prevent damage and to be successful with raising the slab. This information

could be, radiant heat pipes, plumbing or draining pipes, any electrical or other hazards that might be a factor.